Profile

Due to the high content of nickel (Ni) and chromium (Cr), 310S stainless steel has good oxidation resistance, corrosion resistance, acid and alkali resistance. After increasing the content of carbon in austenitic stainless steel, the strength is improved due to its solid solution strengthening effect.

The chemical composition characteristics of austenitic stainless steel are based on chromium and nickel to add molybdenum, tungsten, niobium and titanium, and because of its face-centered cubic structure, it has high strength and creep strength at high temperatures. 310S stainless steel is often used in the manufacture of boiler, steam turbine, industrial furnace and aviation, petrochemical and other parts of the industry.

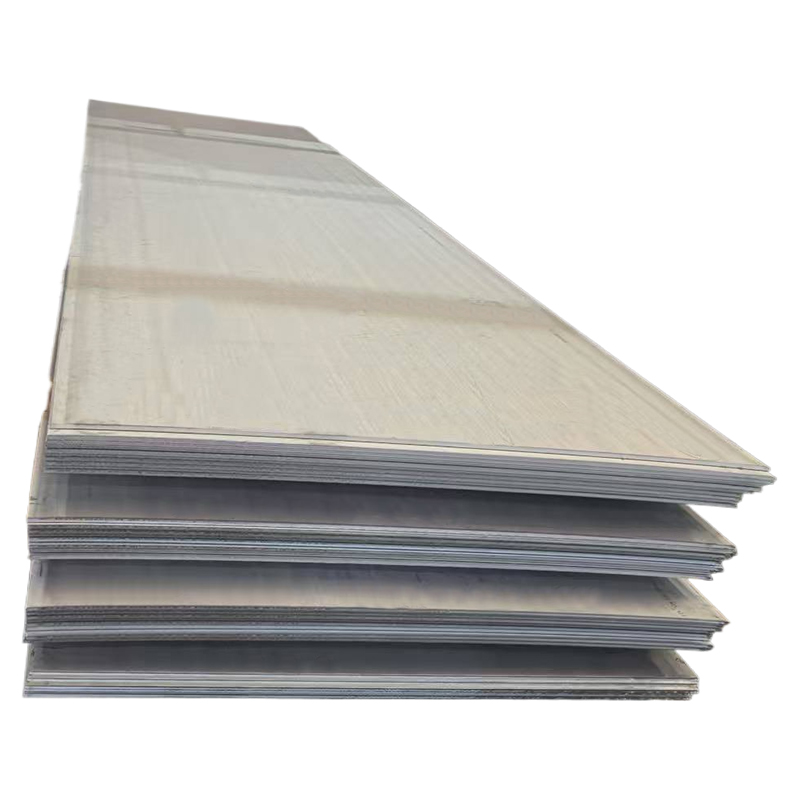

Product Description

|

Product |

310S Stainless Steel Sheet |

|

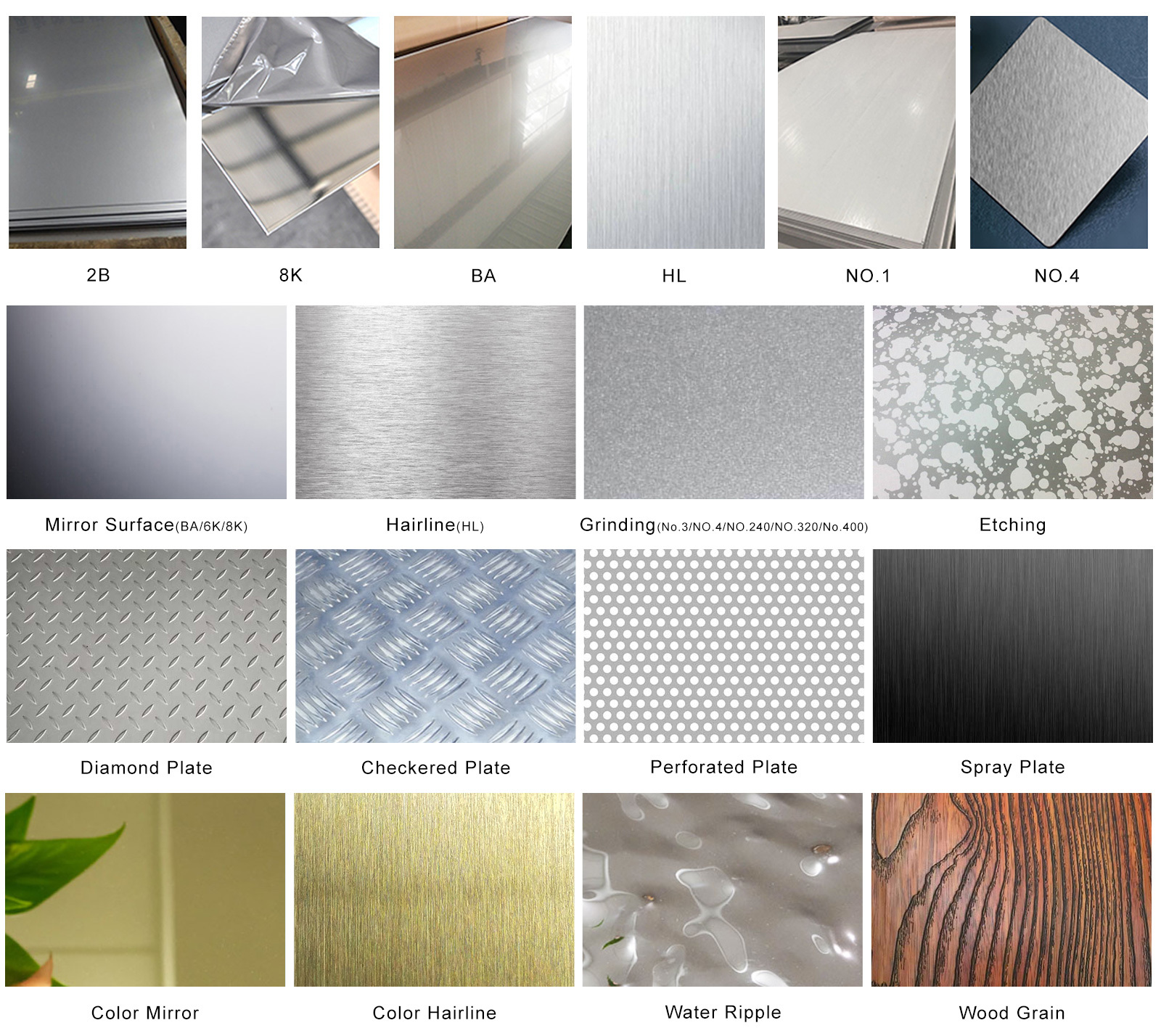

Surface Finish |

BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

|

Technique |

Hot Rolled / Cold Rolled |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

|

Width |

500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

|

Length |

500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

|

Thickness |

0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

|

Material |

201, 202 |

|

Color |

Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

|

Stock Dimension |

Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request |

|

Service |

OEM, Customized processing service, Customized fabrication by drawings |

|

Processing Type |

Cutting, Bending, Stamping, Welding, CNC machining |

|

Cutting Type |

Laser cutting; Water-jet cutting; Flame cutting |

|

Protection |

1. Inter paper available |

|

Application |

Costruction Industry/ Kichten Products/ Fabrication Industry/ Home Decoration |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.08 |

≤1.0 |

≤ 2.0 |

24.0~26.0 |

19.0~22.0 |

≤ 0.03 |

≤ 0.045 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥520 |

≥205 |

≥40 |

≤ 217HB;≤ 95HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

9.01 |

200 |

14.4 |

13.8 |

94 |

Surface Selection

Reviews

There are no reviews yet.