Why Choose Us (Product Advantages)

-

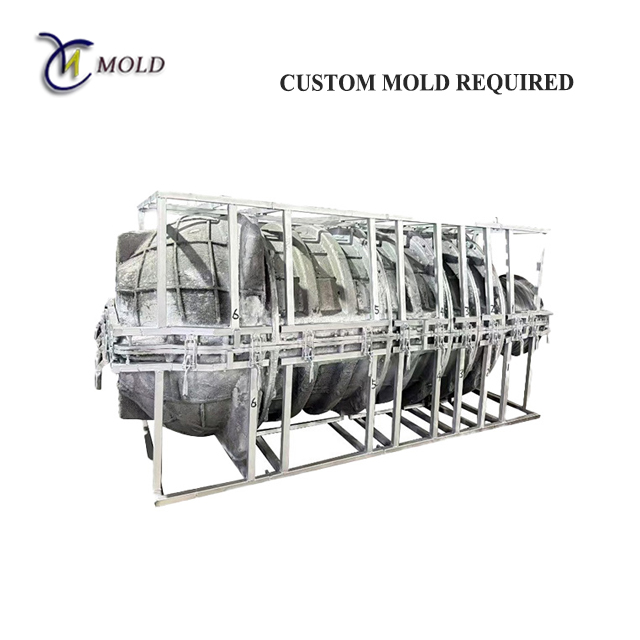

Tailor-Made Solutions – We provide Customized Rotomolding Molds designed to meet specific customer needs, from small plastic parts to large industrial tanks.

-

Durable Material Options – Available in steel rotomolding molds, aluminum rotomolding molds, and fabricated tooling, ensuring long-lasting performance.

-

Advanced CNC & Welding Technology – Precision CNC machining and professional welding guarantee high accuracy and smooth mold surfaces.

-

High Efficiency in Production – Optimized rotational molding tooling design enhances heating/cooling performance and shortens cycle times.

-

Flexible Customization – Choose from single cavity, multi-cavity, open flame, and oven molds, supporting diverse product requirements.

-

OEM & ODM Services – Provide customized rotomolding mould design, prototyping, and tooling development with complete engineering support.

Applications

Our Customized Rotomolding Molds & Rotational Molding Tooling are widely applied in:

-

Water tanks, septic tanks, fuel tanks, and chemical storage tanks

-

Kayaks, canoes, paddle boards, and boats

-

Plastic pallets, crates, bins, containers, and dustbins

-

Outdoor furniture, decorative planters, garden products, landscape items

-

Playground equipment, slides, toys, and recreational facilities

-

Traffic barriers, cones, bollards, and safety products

-

Industrial housings, enclosures, machine covers, and OEM parts

Product Showcase

-

Material Selection – Steel molds, aluminum molds, and hybrid molds available for different production requirements.

-

Surface Options – Smooth finish, textured finish, stone effect, wood grain effect, and custom patterns.

-

Custom Sizes – From small components to large rotomolding molds up to thousands of liters.

-

Engineering Support – 3D design, mold flow analysis, prototyping, and trial runs available.

-

Full-Service Manufacturing – From mold design to fabrication, assembly, testing, and after-sales support.

Factory Strength

l 15+ years of rotomolding experience

l 6 rotomolding machines & CNC tooling capabilities

l In-house assembly line for full product solutions

l ISO & quality certifications

How We Work (Process)

l Requirement Discussion

l Free Design Proposal

l Mould Development

l Sample Confirmation

l Mass Production

l On-Time Delivery

FAQ

Q1: What materials do you use for customized rotomolding molds?

A: We offer carbon steel, stainless steel, and cast aluminum, ensuring durability and thermal efficiency for rotational molding tooling.

Q2: Can I order a custom size or shape?

A: Yes, we provide fully customized rotomolding moulds based on your product drawings, samples, or design concepts.

Q3: How long does it take to produce a custom mold?

A: Typical lead time is 4–8 weeks, depending on mold complexity and size.

Q4: Do you test molds before delivery?

A: Yes, all molds undergo trial production, heating tests, and dimensional inspections to ensure accuracy and performance.

Q5: What industries use your customized rotomolding molds?

A: Our molds are used in water storage, marine industry, logistics, agriculture, construction, playground equipment, outdoor furniture, and traffic safety.

Q6: Can you provide OEM & ODM services?

A: Absolutely. We provide OEM rotomolding tooling solutions and ODM mold development, supporting global brands and manufacturers.

Q7: Are your molds compatible with different machines?

A: Yes, our molds work with carousel machines, shuttle machines, rock-and-roll machines, and clamshell rotomolding machines.

Reviews

There are no reviews yet.