Category: Machinery

Machinery

Showing 33–48 of 105 results

-

Customizable Taper Roller Bearing Outer Ring Lip Grinder

Contact UsThe characteristics and performance of this machine tool; the overall design of the machine tool is small, strong in rigidity, high processing accuracy, discrete size, ditch shape, roundness, and curvature, which can meet the high precision requirements of conical bearing.

-

DD703.40 Fast Speed EDM Drilling Machine

Contact UsThe maximum depth ratio could be 300:1.

3 stage discharge voltage, can drill diameter from 0.2mm to 3.0mm.

XY hard rail, Z and W linear rail,Z with stepper motor.

With DRO for XY,can show the position of XYZ,with depth setting for Z axis.

Auto deep control for blind hole.

Accuracy (hole straightness) is less than 0.05 mm.

Can drill on oblique and curved surface directly.

Fast processing speed and low consumption.

Can use city water as coolant, low cost and no pollution.(Pure water is better) -

DD703.50 EDM Hole Drilling Machine

Contact UsThe maximum depth ratio could be 300:1.

3 stage discharge voltage, can drill diameter from 0.2mm to 3.0mm.

XY hard rail, Z and W linear rail,Z with stepper motor.

With DRO for XY,can show the position of XYZ,with depth setting for Z axis.

Auto deep control for blind hole.

Accuracy (hole straightness) is less than 0.05 mm.

Can drill on oblique and curved surface directly.

Fast processing speed and low consumption.

Can use city water as coolant, low cost and no pollution.(Pure water is better) -

Double Station Reciprocating Feeding Forming Machine

Contact UsDouble Station Reciprocating Feeding Forming Machine

-

Dry oil-free screw compressor Double stage TF132

Contact UsThis is a double-stage dry oil-free screw compressor, available in three models: 280kW, 315kW and 355kW. Volume flow FAD:45.0-65.2m³/min

-

Dual-Station Core Mold Vibration Equipment

Contact UsThis equipment integrates mechanical, electrical, hydraulic, and automatic control technologies. It can produce concrete drainage pipes with various joint forms, featuring high production automation, high production efficiency, and a unique production process.

-

End suction multistage pump

Contact UsFeiyue end suction multistage pump is a multistage high-lift centrifugal pump developed and produced for power plant water treatment, brackish water desalination.

-

End suction multistage pump

Contact UsFeiyue end suction multistage pump is a multistage high-lift centrifugal pump developed and produced for power plant water treatment, brackish water desalination.

-

Engineering Plastic Compounding

Contact UsEngineering plastics modification processing is an effective means to improve the performance of engineering plastics.

-

-

-

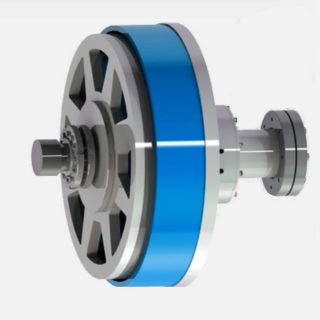

Fixed Speed Basic Model Cylinder Type (FBM-C) Magnetic Coupling

Contact Us● No Physical Connection Between Motor and Load

● Reduce system vibration

● Adjustable Air Gap Spacers

● Accepts Misalignment

● Overload Protection

● For 30 years without maintenance -

Fixed Speed Delay Start (FDS) Delay Protection Magnetic Coupling

Contact Us• There are spacers for torque adjustment

• It has a high tolerance for the center -

FSGJ30D Progressive type safety gear(Single lift)

Contact UsFSGJ30D Single Lift Progressive Type Safety Gear

-

FSGJ60A Progressive type safety gear(Double lift)

Contact UsFSGJ60A Double lift Progressive Elevator Safety Gear

-

FSGJ60A Progressive type safety gear(Single lift)

Contact UsFSGJ60A Single Lift Progressive Type Safety Gear