Profile

304L stainless steel plate is a variant of 304 stainless steel plate with a lower carbon content and is used where welding is required. The lower carbon content minimizes the precipitation of carbides in the heat-affected zone close to the weld, and the precipitation of carbides may cause intergranular corrosion of stainless steel in certain environments.

Basically, using 304L eliminates the need to anneal weld joints prior to using the completed metal form, saving time and effort. Generally speaking, both 304 and 304L stainless steel plates can be used for many of the same applications. The differences are often minor enough that one isn’t considered massively more useful over the other. 304L stainless steel plate is widely used in fields such as food processing equipment, building materials, automobile parts.

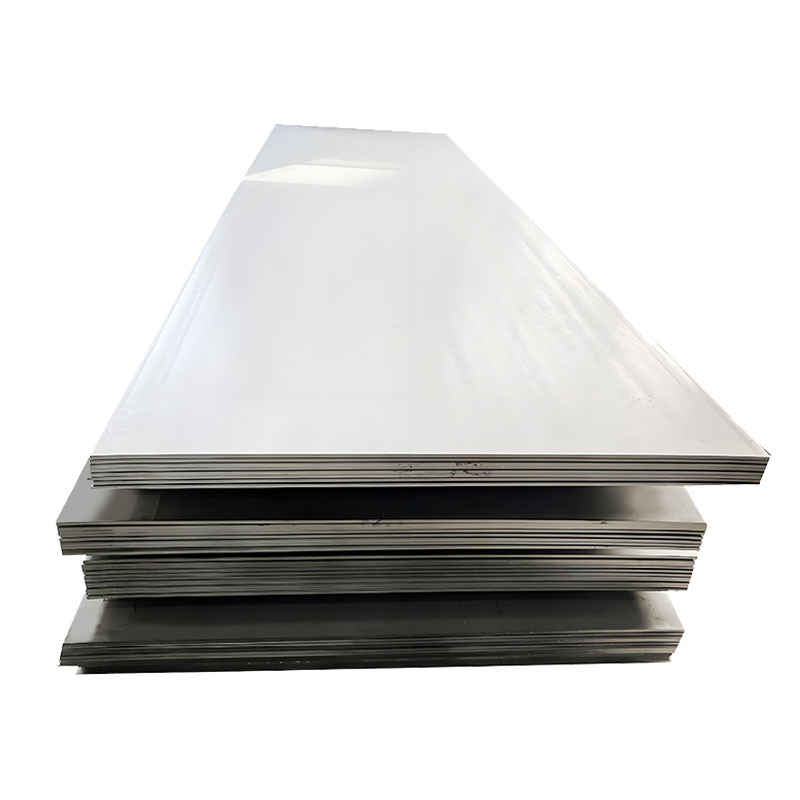

Product Description

|

Product Name |

304L Stainless Steel Plate |

|

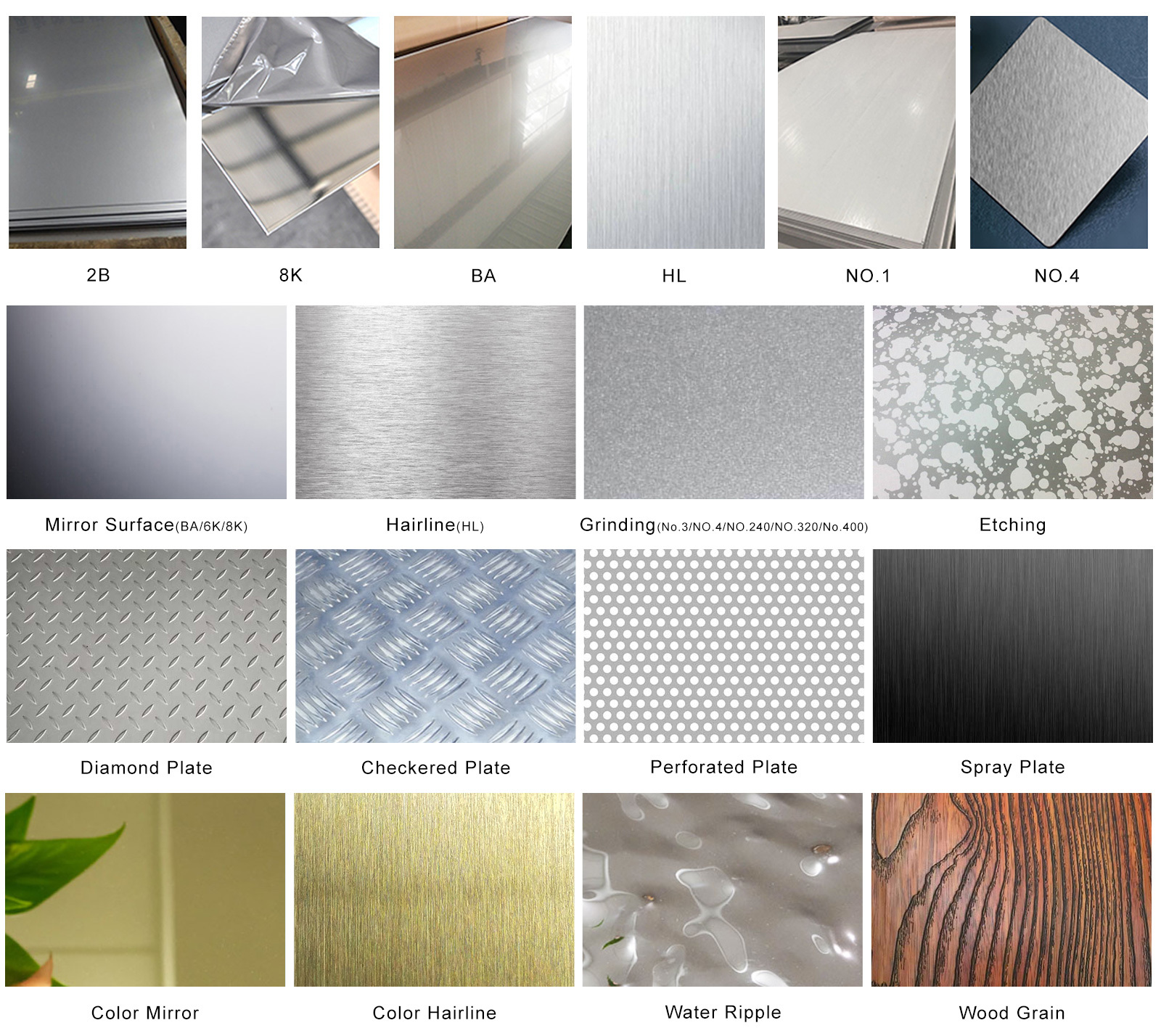

Surface Finish |

BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

|

Technique |

Hot Rolled / Cold Rolled |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

|

Width |

500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

|

Length |

500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

|

Thickness |

0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

|

Material |

201, 202 |

|

Color |

Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

|

Stock Dimension |

Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request |

|

Service |

OEM, Customized processing service, Customized fabrication by drawings |

|

Processing Type |

Cutting, Bending, Stamping, Welding, CNC machining |

|

Cutting Type |

Laser cutting; Water-jet cutting; Flame cutting |

|

Protection |

1. Inter paper available |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.03 |

≤1.0 |

≤ 2.0 |

18.0~20.0 |

8.0~12.0 |

≤ 0.03 |

≤ 0.035 |

Mechanical Properties

|

Tensile StrengthKb (MPa) |

Yield Strengthσ0.2 (MPa) |

ElongationD5 (%) |

Hardness |

|

≥ 520 |

≥ 205 |

≥ 40 |

≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

8.03 |

193 |

16.9 |

16.2 |

72 |

Surface Selection

Reviews

There are no reviews yet.