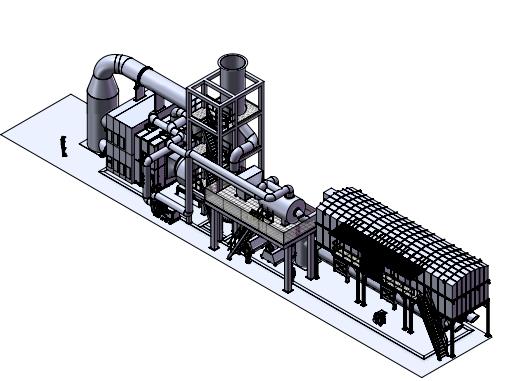

Efficient and safe exhaust air treatment with regenerative thermal oxidizer (RTO)

Regenerative Thermal Oxidizer is an exhausted air treatment machine which collecting the exhausted air

through the safety air valve into the oxidation bed with the temperature over

820℃ to oxidation the organic waste gas into carbon dioxide and water,.In the

highest solvent value of RTO treatment must meet the removal rate of 99.5% or

more (under the premise of odor removal to reach 99.8% standard) RTO using

German original manufacturing technology and German unique high solvent

incineration treatment PLC programming system, It is characterized by using the

most superior air separation valve, High-efficient heat exchange system for the

heat accumulator, With an extremely high treatment efficiency and thermal

efficiency, RTO has a 60% proportion function on the device safety protection

system. To achieve high-quality equipment with high safety level, low operation

cost and excellent gas purification characteristics.

Security guard of RTO regenerative thermal oxidizer for removing VOCS

Safety measures for regenerative thermal oxidizer operation

1. In order to ensure the safety of Regenerative Thermal Oxidizer adopts the fan in the unfinished

negative pressure production operation, the main fan operation is by the Regenerative Thermal Oxidizer

inlet pressure differential set signal value controlled by the frequency

converter, if the differential pressure signal failure main wind chance out of

control, cause the gas pipeline and Regenerative Thermal Oxidizer furnace deformation damage, so we

designed the inlet mechanical relief valve mechanism, when the electrical

failure of the mechanical valve to pressure relief protection.

2. The fresh air cooling valve is set. When the solvent is discharged from

the over temperature of the furnace, there is enough fresh air to ensure the

safe exhaust of clean air.

3. There is a safety ventilation door protection system for collecting pipes.

When the system equipment fails or power off or gas breaks, it can automatically

drain safely to protect the absolute safety of the equipment.

Control and safety systems for gas appliances

1. Temperature control: sensing system, XtraControl™ control device and

XtraBalance© balancing device

2. Pressure control: combustion system and safety system

3. Valve control: gas transmission system and safety system

4. Thermal energy control: energy system and safety system

5. Power control: fan system and safety system

6. LEL detection: the security system

Innovative control and balancing devices for efficient heat exchange

one. XtraControl™ Control device: When the solvent concentration is greater

than 2.5 g / standard cubic meter, the temperature in the heat exchanger is

likely to exceed the temperature in the combustion chamber: a state called

"reverse heat exchange" that increases with the working time of the system. If

not controlled, the bed temperature may reach 1000°C (1830°F), causing an

undesired shutdown failure. XtraControl™ The control mode of the control device

is to avoid this phenomenon. The sensor in the heat exchanger and combustion

chamber will be defined as "average system temperature", so that the combustion

chamber temperature will be adjusted according to the sliding value rather than

the fixed value to ensure that the energy released by the oxidized solvent will

be fully used for the bed safe exchange, reduce the cost operation, and greatly

increase the operation reliability of the system for the energy-saving thermal

bypass device.

two. XtraBalance© Balancing devices: The development of XtraBalance©

balancing devices in Germany is based on years of experience in installation in

different industries. The internal sensor records the temperature change of each

heat exchanger and is then used to calculate the energy difference between the

beds. Through an intelligent energy management system, the relevant results

obtained by the monitoring device are used to automatically adjust the thermal

balance

Energy saving effect of RTO regenerative thermal oxidizer for removing VOCS

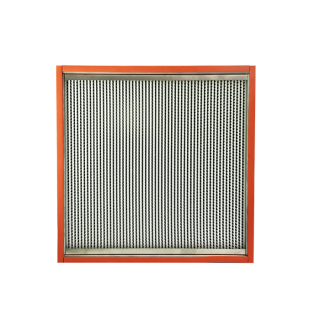

1. The main conditions of Regenerative Thermal Oxidizer energy consumption depends on the heat exchange

efficiency, 820℃ high temperature must be exchanged, generally meet the exchange

conditions, but before the exchange efficiency determines the burner energy

consumption, gas and honeycomb ceramic exchange area 100% face exchange

exchanger is 100% of the heat energy utilization, 60% of the surface contact

exchange is 60% of the heat energy exchange.

2. The technical performance of honeycomb ceramics and the calculation

according to the industrial and mining conditions are also one of the

indispensable and important links.

Remove rate of VOC:

1. The oxidation time of the waste gas in the 800℃ furnace is greater than 1

second, which depends on the flow rate of the treatment gas must be guaranteed

during the oxidation period of Regenerative Thermal Oxidizer.

2. The structural design and sealing material of Regenerative Thermal Oxidizer intake and exhaust

valves are related to whether the leakage can meet 5 ‰

3. The technological treatment of high and low temperature gases entered into

Regenerative Thermal Oxidizer is related to the carbon saving problem of the gas transmission system,

which affects the quality of the emission gas.

4. The insulation standard of the gas transmission system is also the source

of carbon saving, which affects the quality of the emission gas.

What is a regenerative thermal oxidizer?

What are the precautions for using regenerative thermal oxidiser?

How to choose a suitable regenerative thermal oxidizer manufacturer?

Reviews

There are no reviews yet.