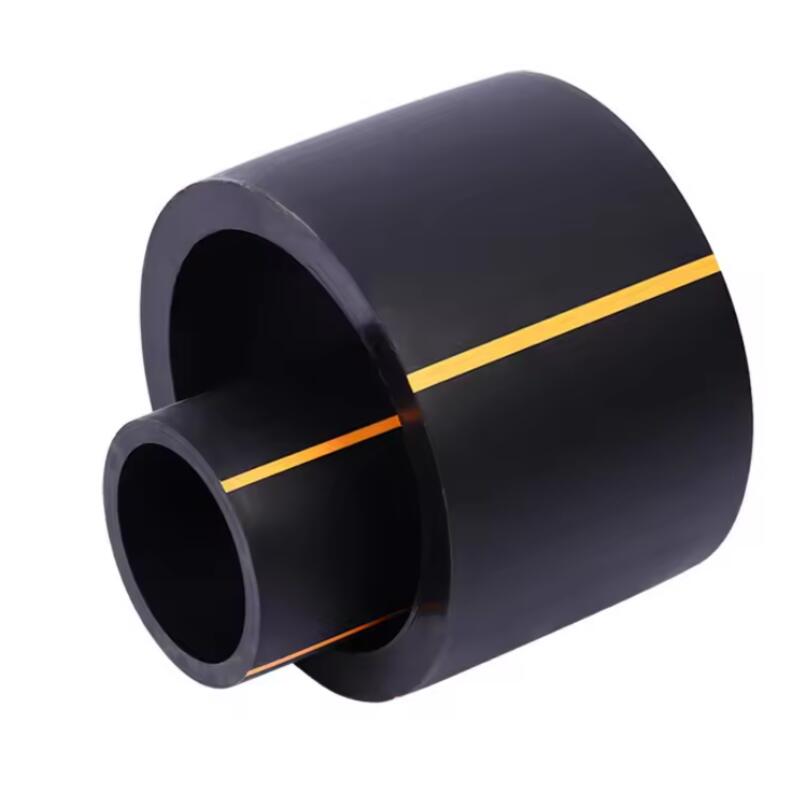

Key Features of HDPE Gas Transmission Pipe for sale

High strength, stress crack resistance, and excellent creep resistance ensure

reliability under demanding conditions.

Remarkable toughness, flexibility, and adaptability to uneven terrains and

seismic activities make it suitable for challenging environments prone to

earthquakes and typhoons.

Superior weather resistance, including UV resistance, coupled with long-term

thermal stability, guarantees durability and longevity.

Corrosion resistance and a prolonged service life make it an ideal choice for

transporting natural gas, liquefied petroleum gas, and coal gas.

Smooth inner wall design facilitates high flow capacity, allowing gas flow

rates of up to 20m/s, thereby reducing operating costs over time.

|

SDR Ratings |

SDR11 |

SDR17.6 |

|

Diameter |

Wall Thickness |

|

|

DN(mm) |

e (mm) |

|

|

20 |

2.3 |

2.3 |

|

25 |

2.3 |

2.3 |

|

32 |

3.0 |

2.3 |

|

40 |

3.7 |

2.3 |

|

50 |

4.6 |

2.9 |

|

63 |

5.8 |

3.6 |

|

75 |

6.8 |

4.3 |

|

90 |

8.2 |

5.2 |

|

110 |

10.0 |

6.3 |

|

160 |

14.6 |

9.1 |

|

200 |

18.2 |

11.4 |

|

250 |

22.7 |

14.2 |

|

315 |

28.6 |

17.9 |

|

400 |

36.3 |

22.7 |

|

500 |

45.4 |

28.4 |

|

Longitudinal Reversion, % (110℃) |

<=3 |

|

Oxidation Induction Time, min, (200℃) |

>=20 |

|

Extension Rate at Break, % |

>=350 |

|

Carbon Black Content (mass fraction), % (only applies to black mixed ingredients) |

2.0-2.5 |

|

Melt Mass Flow Rate, g/10min (195℃, 5kg) |

Change of MFR by processing ±2 |

|

Longitudinal Reversion Rate,h(80℃, 2Mpa) |

≥20 |

|

Hydrostatic Strength |

|

|

1) 20℃, Hoop Stress: |

|

|

PE 100, 12.4 MPa, PE80 9.0Mpa, 100H |

No Failure |

|

2)80℃, Hoop Stress: |

|

|

PE 100, 5.4 MPa, PE80 4.5Mpa, 165H |

No Failure |

|

3)80℃, Hoop Stress: |

|

|

PE 100, 5.0 MPa, PE80 4.0Mpa, 1000H |

No Failure |

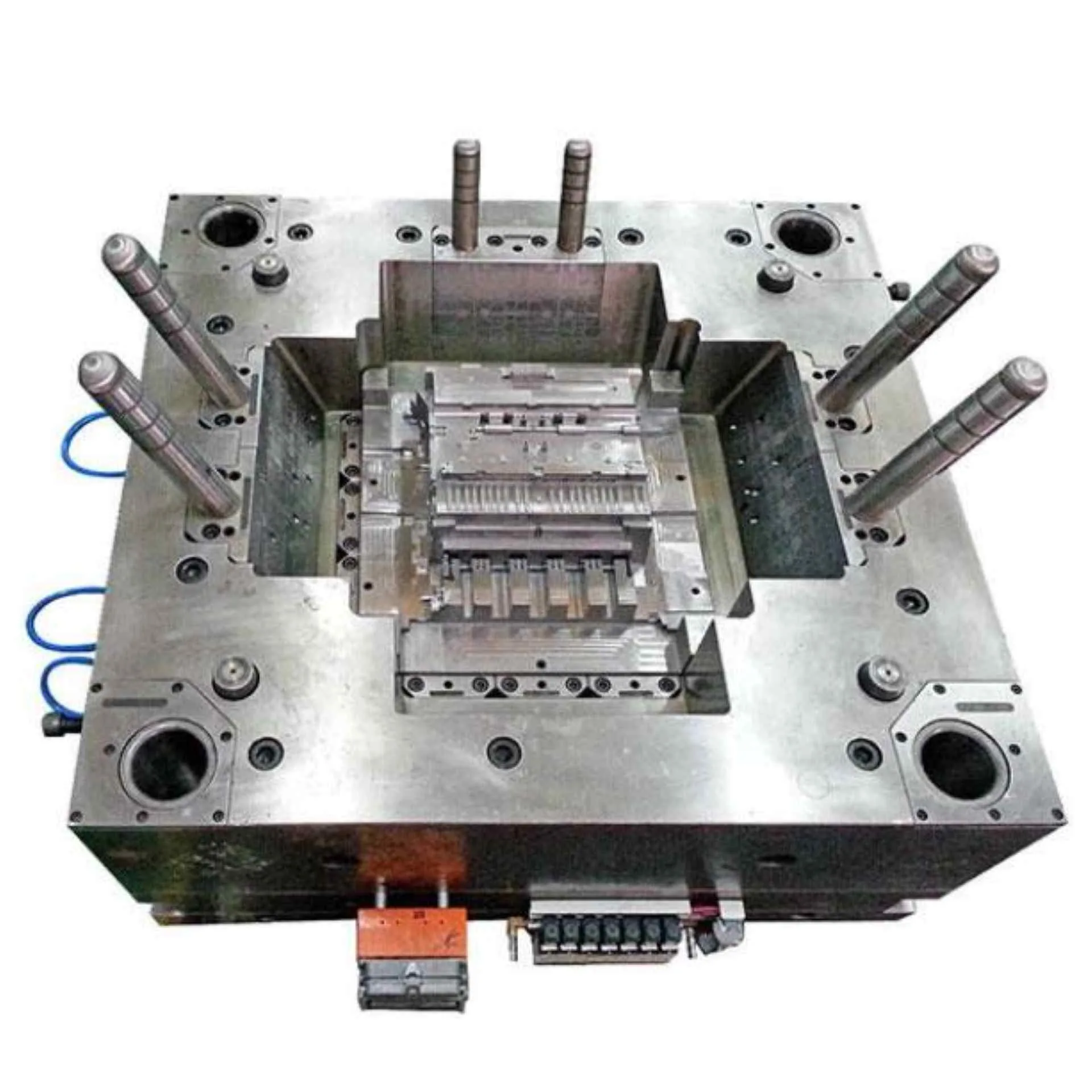

HDPE Gas Transmission Pipe Manufacturing Process

1. High-Density Polyethylene (HDPE):

The HDPE gas transmission pipe fittings for sale are manufactured using HDPE, a durable and flexible thermoplastic material known for its excellent resistance to corrosion, chemicals, and weathering.

2. Extrusion Process:

The manufacturing process involves extruding the HDPE material through a die, which shapes it into a continuous pipe. This extrusion process ensures a consistent and uniform pipe diameter, wall thickness, and overall quality.

3. Co-extrusion Technology:

Some HDPE gas transmission pipes are manufactured using co-extrusion technology, where multiple layers of HDPE with different properties are combined. This enhances the pipe's strength, durability, and resistance to environmental factors.

4. Fusion Welding:

HDPE gas transmission pipes are joined using fusion welding techniques. This creates strong and leak-free joints, ensuring the integrity of the gas transmission system.

5. Quality Control:

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the pipes meet industry standards and specifications. This includes testing for dimensional accuracy, strength, and resistance to pressure and impact.

6. Longevity and Reliability:

HDPE gas transmission pipes are designed to have a long service life, with a proven track record of durability and reliability. They are resistant to corrosion, abrasion, and chemical attack, making them suitable for various gas transmission applications.

7. Environmental Benefits:

HDPE gas transmission pipes are environmentally friendly, as they are recyclable and have a low carbon footprint. They contribute to sustainable development and reduce the impact on the environment compared to other materials used for gas transmission.

8. Compliance:

The manufacturing process and the resulting HDPE gas transmission pipes comply with relevant industry standards and regulations, ensuring the safety and reliability of gas transmission systems.

Why Choose Hangyi?

Rich Experience:

With a wealth of experience in supplying piping systems, we are industry experts.

Comprehensive Solutions:

We offer complete piping systems, ensuring you always find the perfect solution with us.

Professional After-Sales Support:

Our committed after-sales team provides expert installation guidance, ensuring smooth implementation.

Top-Quality Materials:

We use premium raw materials, backed by a long warranty period, guaranteeing the quality of our products.

Prompt Response:

Expect quick replies to your inquiries within 24 hours, ensuring efficient communication.

OEM Service:

We offer OEM services to support successful sales in your market, tailored to your needs.

Expanded Warehousing:

With a dedicated 30,000 square meter professional warehouse, our best-selling products are readily available in stock, meeting your delivery deadlines seamlessly.

Hangyi is the high-quality HDPE gas transmission pipe manufacturer and seller. It is well-known and popular at home and abroad. Welcome to contact our gas pipeline!

Related news of HDPE Gas Pipe

Widespread applications of HDPE gas pipes in modern infrastructure

Daily maintenance of hdpe gas transmission pipe fitting

Manufacturing process of HDPE gas transmission pipe

Advantages of HDPE gas transmission pipe fittings

How to pack and transport HDPE gas transmission pipe fittings?

Reviews

There are no reviews yet.