Basic Info

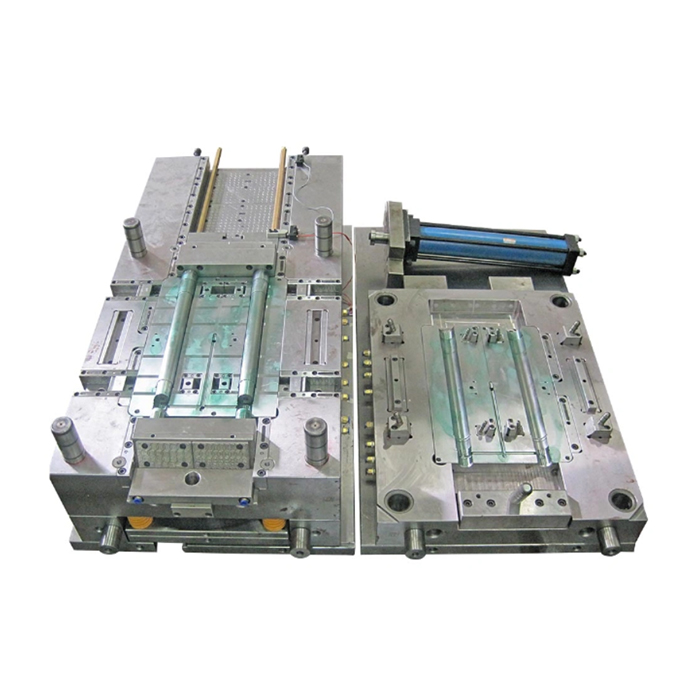

Model: 005

Runner: cold runner

Design software: UG

Standard: MISUMI

Customization: Customization

Mold material: S50c, NAK80, 738 heat treatment, SKD61 heat treatment

Application: Vacuum cleaner extension tube

Packaging: General packaging

Specifications: 1950*700*500

Origin: China

Product Description

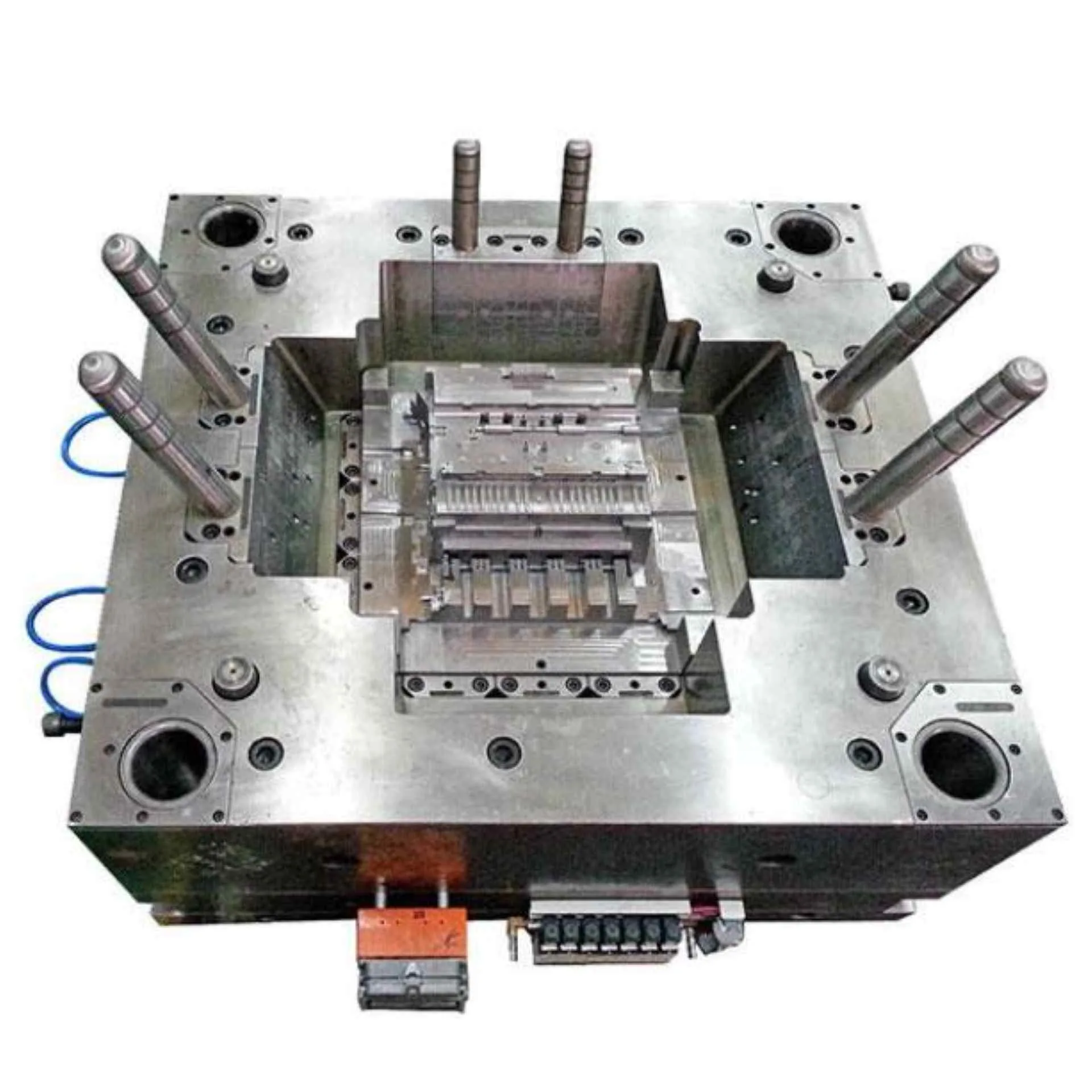

1. Product Specifications: Vacuum Cleaner Plastic Injection Mold

Injection mold

Mold cavity: double type

Mold runner: cold runner

Mold life: 500,000 injections

Plastic parts material: PP

Color of plastic parts: black, red, any other color according to customer's

request or according to RAL code.

Surface of plastic parts: painting, silk screen printing, polishing,

electroplating, etc. the

Plastic parts capacity: maximum weight 110 grams; maximum size 380mmX60mm

Application field: Vacuum cleaner extension tube

Features of vacuum cleaner extension tube injection mold provide

– Made of high-quality materials for durability and longevity

– Precise and accurate molding for a perfect fit with the vacuum cleaner

– Easy to install and remove for convenient use

– Smooth surface finish for easy cleaning and maintenance

– Compatible with a wide range of vacuum cleaner models and brands

– Designed to withstand high pressure and temperature for reliable performance

– Lightweight and compact for easy storage and transportation

– Cost-effective solution for replacing damaged or worn-out extension tubes.

Mold vacuum cleaner produced and provided by Shenzhen Xuzhong has been recognized by a large number of overseas customers. Welcome customers to come to consult our vacuum cleaner mold!

2. Our advantages:

· ISO9001:2015 , ISO14001:2015 certification

· Professional and experienced staff · Production complies with DIN, IS,

ASTM, JIS standards

· Provide standard and non-standard services

· 95% of products are exported abroad.

3. Our service:

1. Offering OEM/ODM services

2. Providing professional plastic mold design and manufacturing services

3. Providing plastic part printing/coating/spraying services

4. Providing plastic part assembly services

5. Providing plastic part packaging services

6. Providing after-sales service

7. Providing samples

8. Customize various non-standard plastic parts according to your drawings

and samples.

9. Specializing in various injection molding parts for various applications

such as household, industrial, automotive, electronic, etc.

10. Produce products according to your drawings, samples, we are willing to

provide you with competitive prices, good quality, timely delivery and

professional services.

11. If you are interested in any of our series, or have OEM requirements to

be met, please feel free to contact us for more details.

12. We warmly welcome customers from all over the world and look forward to

establishing a stable and long-term business relationship with you.

FAQ

1. Q1. When can I get the quotation?

A: We usually quote within 2 days after we get the inquiry, or give feedback

within 1 day, if there are any problems with the prints that need to be

confirmed.

Q2. How long is the lead time for molds?

A: Usually it depends on the size and complexity of the mould. But normally,

the delivery time is about 30~60 days.

Q3. I don't have a 3D drawing, how do I start a new project?

A: You can provide us samples and we will help to build 3D models

accordingly.

Q4. How to ensure product quality before delivery?

A: We have a strict development process. During the sample development

process, we provide samples through trial production, and keep in touch with

customers to meet customer requirements before delivery.

Contact us:

Name: xuzhong Technology (Shenzhen) Co., Ltd.

Tel: 0086-755-29876529

Phone/WeChat/WhatsApp: 0086-18028750185

Email: jinyong329@gmail.com

Address: 4Q, Jinda City Building, Xiner Community, Xinqiao Street, Baoan

District, Shenzhen, Guangdong Province

Related Keywords: Auto Interior Injection Mold, Auto Interior Injection Mold

Design, Auto Interior Mold, China, Shenzhen, Plastic Mold, Injection Mold

Related news of vacuum plastic injection mold

Regular maintenance of vacuum cleaner mold: A comprehensive guide

The maintenance of vacuum cleaner tube injection molds

Features of vacuum cleaner injection mold

Benefits of vacuum cleaner extension tube injection mold

Convenient Vacuum Cleaner Extension Tube Injection Mold For Sale

Manufacturing process of precise vacuum cleaner injection mold

Use of vacuum cleaner molds in the product manufacturing process

Production process of customizable vacuum cleaner plastic injection molds

Reviews

There are no reviews yet.