Brand: Bettter Tech

Place Of Origin: China

Status: New

Machine Type: Cold Forging Machine

Core Components: Plc, Motor

Warranty Period: 1 Year

Core Selling Point: High Productivity

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Applicable Industry: Manufacturing Plant

Packaging: Plywood Case

Productivity: 60sets/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 60sets/Month

HS Code: 847480

Port: Shanghai

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF,EXW,FCA

-

Selling Units:Set/Sets

-

Package Type:Pallet/Case

-

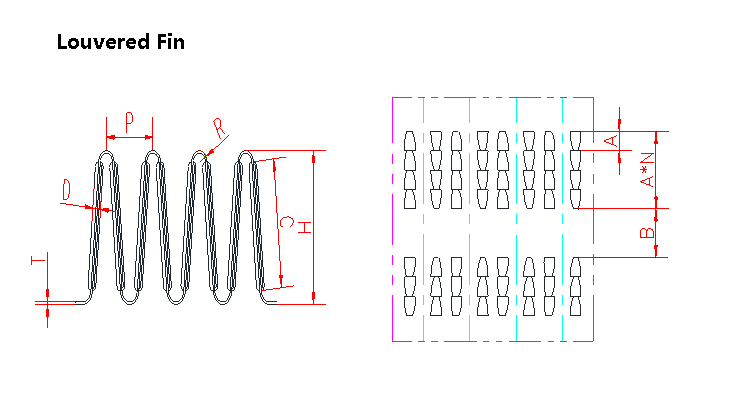

Fins are the important parts for heat exchanger, which heat is transferred through. Heat exchanger Fin Rolling Machine can directly make metal foil such as aluminum foil, copper foil into required fins by rolling form. The typical fins are louvered fin, zig zag fin, corrugated fin/wavy fin, plain fin/straight fin/ Rectangle Fin and more. The fin profile can be customized upon your request. The Heat Exchanger Fin rolling machine is also called as Star Die Fin Machine because of its star-shape tooling blades. The rolling Fin Machine includes automatic uncoiller, automatic tensioning device, automatic lubricating system, automatic fin forming, automatic cutting fin, etc in a skid-mount type with compact structure. The Zig Zag Fin Machine adopts PLC control, touch screen operation which is easy to be operated.

-

Heat exchanger fin rolling machine’s biggest advantage is fast with feeding speed of 100-120m/min which is in high efficiency, high precision and stable performance. If your heat exchanger fin can be formed by rolling and in big demands, the rolling fin machine is suitable for your fin production. Comparing to fin punching/stamping/pressing machine, the fin rolling machine’s mold is fixed in fin shape, fin height, fin pitch. If have different strip width, it need be designed well in advance.

-

Better-Tech specializes in supplying the full set of fin forming solution from Heat Exchanger Fins to fin machines and fin molds. Upon fin specification or fin drawing, we can supply the optimized configuration to produce your desirable radiator fins.

-

Louvered Fin Drawing for reference.

-

-

Louvered Fin/Zig Zag Fin Photo

-

-

Fin with Bumps

-

-

Plain Fin/ Rectangle Fin

-

T

Reviews

There are no reviews yet.